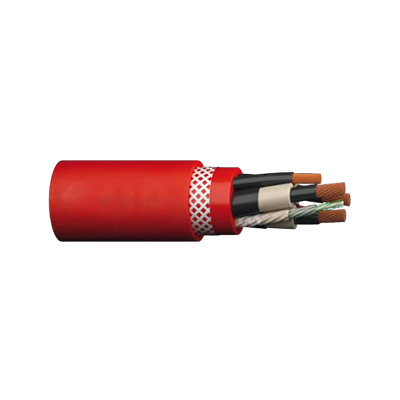

F-(N)TSCGEWOEU Cable Construction

| Conductor | Electrolytic copper, not tinned, very finely stranded (class 5) |

| Insulation | PROTOLON, Basic material: EPR, Compound type: Special compound, better 3GI3 |

| Electrical field control | Inner and outer layer of semiconductive rubber compound |

| Core identification | Natural coloring with black semiconductive rubber on which white digits 1 to 3 are printed |

| Core arrangement | Three main conductors laid-up, with protective-earth conductor split into 3 in the outer interstices |

| Inner sheath | Basic material: EPR, Compound type: Special compound |

| Outer sheath | Basic material: Synthetic elastomer compound e.g. CM, Compound type: better 5GM3, Color: Red |

F-(N)TSCGEWOEU Cable Application

- For use along conveyor belts (also suitable for mobile equipment) and material handling machinery

- Connecting submersible pump installations

- Suitable for cable conduit installations on land, underwater, outdoors, indoors, and in power plants, industrial facilities, and distribution networks

- Continuous slight movement on lifting equipment or bucket wheel excavators, such as free suspension or torsion.

F-(N)TSCGEWOEU Cable Technical Data

| Rated voltage | 3.6/6 kV | 6/10 kV | 8.7/15 kV | 12/20 kV |

| Max. permissible operating voltage AC | 4.2/7.2 kV | 6,9/12 kV | 10.4/18 kV | 13.9/24 kV |

| Max. permissible operating voltage DC | 5.4/10.8 kV | 9/18 kV | 13.5/27 kV | 18/36 kV |

| AC test voltage - main cores | 11 kV ( 5 Min.) | 17 kV ( 5 Min.) | 24 kV ( 5 Min.) | 29 kV ( 5 Min.) |

| Max. operating temperature of the conductor | 90 °C | |||

| Max. short circuit temperature of the conductor | 250 °C | |||

| Ambient temperature for fixed installation | min -40 °C ; max +80 °C | |||

| Ambient temperature in fully flexible operation | min -25 °C ; max +60 °C | |||

| Max. tensile load on the conductor | 15 N/mm² | |||

| Torsional stress +/- | 100 °/m | |||

| Bending radii min. | Acc. to DIN VDE 0298 part 3 | |||

| Additional tests | Torsional StressTest, Roller Bending Test Type C |

F-(N)TSCGEWOEU Cable Standard

- Based on DIN VDE 0250-813

F-(N)TSCGEWOEU Cable Feature

- Exceptional durability and abrasion resistance.

- Highly flexible dynamic movement.

- Oil, flame, and weather resistance.

- Built-in grounding shield and armored safety.

- 3.6/6kv F-(N)TSCGEWOEU Cable Specification

- 6/10kv F-(N)TSCGEWOEU Cable Specification

- 8.7/15kv F-(N)TSCGEWOEU Cable Specification

- 12/20kv F-(N)TSCGEWOEU Cable Specification

- 14/25kv F-(N)TSCGEWOEU Cable Specification

- 18/30kv F-(N)TSCGEWOEU Cable Specification

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 40.1 | 43.1 | 2650 |

| 3×25+2×50/2+1×(6LWL) | 42.4 | 45.4 | 3060 |

| 3×35+2×25/2+1×(6LWL) | 42.3 | 45.3 | 3060 |

| 3×35+2×50/2+1×(6LWL) | 44 | 47 | 3410 |

| 3×50+2×25/2+1×(6LWL) | 43.8 | 46.8 | 3490 |

| 3×50+2×50/2+1×(6LWL) | 46.1 | 49.1 | 3640 |

| 3×70+2×35/2+1×(6LWL) | 47 | 50 | 4350 |

| 3×70+2×50/2+1×(6LWL) | 52 | 56 | 5280 |

| 3×95+2×50/2+1×(6LWL) | 52.2 | 56.2 | 5550 |

| 3×120+2×70/2+1×(6LWL) | 49.6 | 50.9 | 7040 |

| 3×150+2×70/2+1×(6LWL) | 48.4 | 52.3 | 8000 |

| 3×185+2×95/2+1×(6LWL) | 51.3 | 55.3 | 9310 |

| 3×240+2×120/2+1×(6LWL) | 58 | 62 | 11940 |

| 3×300+2×150/2+1×(6LWL) | 63.2 | 67.2 | 14230 |

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 41.4 | 44.4 | 2770 |

| 3×25+2×50/2+1×(6LWL) | 43.1 | 46.1 | 3120 |

| 3×35+2×25/2+1×(6LWL) | 43.6 | 46.6 | 3190 |

| 3×35+2×50/2+1×(6LWL) | 44.7 | 47.7 | 3470 |

| 3×50+2×25/2+1×(6LWL) | 45.1 | 48.1 | 3620 |

| 3×50+2×50/2+1×(6LWL) | 46.8 | 49.8 | 4010 |

| 3×70+2×35/2+1×(6LWL) | 48.3 | 51.3 | 4500 |

| 3×70+2×50/2+1×(6LWL) | 52.7 | 56.7 | 5360 |

| 3×95+2×50/2+1×(6LWL) | 53.5 | 57.5 | 5710 |

| 3×120+2×70/2+1×(6LWL) | 57.2 | 61.2 | 6830 |

| 3×150+2×70/2+1×(6LWL) | 62.3 | 66.3 | 8180 |

| 3×185+2×95/2+1×(6LWL) | 65.3 | 69.3 | 9500 |

| 3×240+2×120/2+1×(6LWL) | 73.4 | 77.4 | 12160 |

| 3×300+2×150/2+1×(6LWL) | 78.6 | 82.6 | 14460 |

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 44.2 | 47.2 | 3050 |

| 3×25+2×50/2+1×(6LWL) | 45.4 | 48.4 | 3350 |

| 3×35+2×25/2+1×(6LWL) | 45.3 | 48.3 | 3320 |

| 3×35+2×50/2+1×(6LWL) | 47 | 50 | 3710 |

| 3×50+2×25/2+1×(6LWL) | 49.4 | 53.4 | 4160 |

| 3×50+2×50/2+1×(6LWL) | 51.2 | 55.2 | 4590 |

| 3×70+2×35/2+1×(6LWL) | 52.7 | 56.7 | 5080 |

| 3×70+2×50/2+1×(6LWL) | 55 | 59 | 5640 |

| 3×95+2×50/2+1×(6LWL) | 57 | 61 | 6160 |

| 3×120+2×70/2+1×(6LWL) | 62.1 | 66.1 | 7520 |

| 3×150+2×70/2+1×(6LWL) | 65.7 | 69.7 | 8670 |

| 3×185+2×95/2+1×(6LWL) | 68.7 | 72.7 | 10010 |

| 3×240+2×120/2+1×(6LWL) | 76.8 | 80.8 | 12730 |

| 3×300+2×150/2+1×(6LWL) | 82 | 86 | 15080 |

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 45.5 | 48.5 | 3140 |

| 3×25+2×50/2+1×(6LWL) | 47.2 | 50.2 | 3530 |

| 3×35+2×25/2+1×(6LWL) | 48.3 | 51.3 | 3640 |

| 3×35+2×50/2+1×(6LWL) | 51 | 55 | 4240 |

| 3×50+2×25/2+1×(6LWL) | 52.5 | 56.5 | 4530 |

| 3×50+2×50/2+1×(6LWL) | 52.5 | 56.5 | 4690 |

| 3×70+2×35/2+1×(6LWL) | 55.7 | 59.7 | 5460 |

| 3×70+2×50/2+1×(6LWL) | 58 | 62 | 6040 |

| 3×95+2×50/2+1×(6LWL) | 61.4 | 65.4 | 6770 |

| 3×120+2×70/2+1×(6LWL) | 65.1 | 69.1 | 7950 |

| 3×150+2×70/2+1×(6LWL) | 68.7 | 72.7 | 9130 |

| 3×185+2×95/2+1×(6LWL) | 73.2 | 77.2 | 10770 |

| 3×240+2×120/2+1×(6LWL) | 79.8 | 83.8 | 13260 |

| 3×300+2×150/2+1×(6LWL) | 86.3 | 91.3 | 16040 |

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 50.3 | 54.3 | 3740 |

| 3×25+2×50/2+1×(6LWL) | 50.3 | 54.3 | 3900 |

| 3×35+2×25/2+1×(6LWL) | 53.1 | 57.1 | 4270 |

| 3×35+2×50/2+1×(6LWL) | 53.1 | 57.1 | 4440 |

| 3×50+2×25/2+1×(6LWL) | 56.3 | 60.3 | 5000 |

| 3×50+2×50/2+1×(6LWL) | 56.3 | 60.3 | 5160 |

| 3×70+2×35/2+1×(6LWL) | 61 | 65 | 6190 |

| 3×70+2×50/2+1×(6LWL) | 61 | 65 | 6390 |

| 3×95+2×50/2+1×(6LWL) | 65.3 | 69.3 | 7340 |

| 3×120+2×70/2+1×(6LWL) | 69 | 73 | 8550 |

| 3×150+2×70/2+1×(6LWL) | 74 | 78 | 10020 |

| 3×185+2×95/2+1×(6LWL) | 77 | 81 | 11410 |

| 3×240+2×120/2+1×(6LWL) | 85 | 90 | 14380 |

| 3×300+2×150/2+1×(6LWL) | 90.2 | 95.2 | 16820 |

| Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. ×mm^2 | mm | mm | kg/km |

| 3×25+2×25/2+1×(6LWL) | 53.7 | 57.7 | 4140 |

| 3×25+2×50/2+1×(6LWL) | 53.7 | 57.7 | 4310 |

| 3×35+2×25/2+1×(6LWL) | 56.6 | 60.6 | 4720 |

| 3×35+2×50/2+1×(6LWL) | 56.6 | 60.6 | 4880 |

| 3×50+2×25/2+1×(6LWL) | 61.2 | 65.2 | 5680 |

| 3×50+2×50/2+1×(6LWL) | 61.2 | 65.2 | 5840 |

| 3×70+2×35/2+1×(6LWL) | 64.4 | 68.4 | 6670 |

| 3×70+2×50/2+1×(6LWL) | 64.4 | 68.4 | 6870 |

| 3×95+2×50/2+1×(6LWL) | 68.7 | 72.7 | 7860 |

| 3×120+2×70/2+1×(6LWL) | 73.8 | 77.8 | 9350 |

| 3×150+2×70/2+1×(6LWL) | 77.5 | 81.5 | 10630 |

| 3×185+2×95/2+1×(6LWL) | 80.5 | 84.5 | 12040 |

| 3×240+2×120/2+1×(6LWL) | 88.5 | 93.5 | 15070 |

| 3×300+2×150/2+1×(6LWL) | 94.7 | 99.7 | 17780 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees