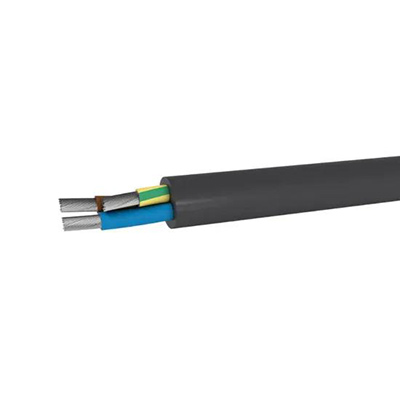

07RC4N-F Cable Construction

| CONDUCTOR: | Electrolytic annealed, class 5 stranded plain copper wires (tinned conductor on request) |

| SEPERATOR: | A suitable tape may be applied over the conductor |

| INSULATION: | EI4 type cross-linked elastomeric compound, EPR (EN 50363-1) |

| INNER SHEATH: | EM2 or EM3 type cross-linked elastomeric compound (EN 50363-2-1) If outer sheath thickness is greater than 2,4 mm |

| SCREEN: | Tinned copper wire braiding |

| OUTER SHEATH: | EM2 type cross-linked elastomeric compound (EN 50363-2-1) |

| COLOR: | Black (other colors available on request) |

07RC4N-F Cable Application

07RC4N-F cable is suitable for power transmission, control, and signal transmission in open factories, industrial sites, power tools, and mobile equipment. It can be used in heavy-duty conditions and environments with moderate mechanical stress. Its shielded design resists electromagnetic interference, and with its special construction, it can be used indoors, outdoors, in damp, oily, humid locations, and in potentially explosive atmospheres.

- Industrial Machinery: Power cables for machine tools, conveyors, and robots.

- Construction Sites: Heavy-duty trailing cables for site equipment and temporary power supply.

- Welding Cables: Widely used, particularly in neutral conductor-reduced variants.

- Stage & Event Power: Suitable for portable power distribution scenarios requiring both durability and flexibility.

- Mining and Quarrying: Suitable for non-extreme conditions in these sectors.

- Marine and Offshore: Meets deck and engine room requirements for oil resistance and weather resistance.

07RC4N-F Cable Characteristics

| RATED VOLTAGE: | 450/750 V (U0/U) |

| AC TEST VOLTAGE: | 2,5 kV |

| OPERATING TEMPETATURE | |

| IN FLEXING USE: | -25°C to +60°C |

| IN FIXED USE: | -40°C to +90°C |

| CONDUCTOR SHORT-CIRCUIT TEMP.: | 200°C (Max. 5 sec) |

| MIN. INSTALLATION TEMP.: | -25°C |

| MIN. BENDING RADIUS: | Based on EN 50565-1 Tab. 3 |

| CURRENT CARRYING CAPACITIES: | VDE 0298-4 Tab.13 , IEC 60364-5-52 Tab. B.52.12 & Tab. C.52.1 |

07RC4N-F Cable Standard

| Construction | Based on EN 50525-2-21, VDE 0285-2-21, IEC 60245-4 |

| General Requirements | EN 50525-1, VDE 0285-525-1, IEC 60245-1 |

| Guide to Use | EN 50565-1/2, VDE 0298-565-1 |

| Electrical Tests | EN 50395, IEC 60245-2 |

| Non-electrical Tests | EN 50396, IEC 60245-2 |

| Conductor Resistance | IEC 60228, VDE 0295 |

| Flame Retardant | IEC 60332-1-2, VDE 0482-332-1-2 |

| Oil Resistant | EN 60811-404, VDE 0473-811-404 |

07RC4N-F Cable Feature

- Excellent heat resistance: EPR typically withstands continuous operating temperatures up to 90°C and higher short-term exposure to elevated temperatures without rapid degradation in high-heat environments.

- Superior aging and ozone resistance: Compared to standard PVC, it better resists cracking and deterioration caused by oxygen, ozone, and prolonged weathering.

- Good moisture resistance: Performs well in humid conditions.

- Exceptional durability: Offers outstanding resistance to abrasion, cutting, crushing, and impact, withstanding rough handling and harsh industrial conditions.

- Weather resistance, oil resistance, and chemical resistance: Resists UV radiation, ozone, and aging, while withstanding exposure to various oils and chemicals.

- Flame retardancy: Chloroprene rubber possesses inherent flame-retardant properties, enabling self-extinguishing capabilities.

07RC4N-F Cable Specification

| Cross Section (mm²) | Nominal Overall Diameter (mm) | Approximate Weight (kg / km) | Min.Bending Radius (free movement) (mm) | Max. Resistance of Conductors at 20°C (ohm / km) |

|---|---|---|---|---|

| 1×16 | 12,50 | 295 | 75 | 1,21 |

| 1×25 | 14,90 | 423 | 89 | 0,78 |

| 1×35 | 16,20 | 539 | 97 | 0,554 |

| 1×50 | 18,50 | 722 | 111 | 0,386 |

| 1×70 | 20,80 | 975 | 125 | 0,272 |

| 1×95 | 23,40 | 1257 | 140 | 0,206 |

| 1×120 | 25,50 | 1545 | 153 | 0,161 |

| 1×150 | 27,70 | 1879 | 166 | 0,129 |

| 1×185 | 30,40 | 2255 | 182 | 0,106 |

| 1×240 | 34,10 | 296 | 205 | 0,0801 |

| 1×300 | 37,10 | 3579 | 223 | 0,0641 |

| 2×1,5 | 12,50 | 216 | 75 | 13,30 |

| 2×2,5 | 14,10 | 280 | 85 | 7,98 |

| 2×4 | 15,70 | 358 | 94 | 4,95 |

| 2×6 | 17,20 | 442 | 103 | 3,30 |

| 2×10 | 20,60 | 660 | 124 | 1,91 |

| 2×16 | 23,00 | 862 | 138 | 1,21 |

| 2×25 | 28,10 | 1277 | 169 | 0,78 |

| 2×35 | 30,40 | 1576 | 182 | 0,554 |

| 3×1 | 12,30 | 211 | 74 | 19,50 |

| 3×1,5 | 13,10 | 243 | 79 | 13,30 |

| 3×2,5 | 14,90 | 323 | 89 | 7,98 |

| 3×4 | 16,60 | 418 | 100 | 4,95 |

| 3×6 | 18,20 | 523 | 109 | 3,30 |

| 3×10 | 22,20 | 806 | 133 | 1,91 |

| 3×16 | 24,60 | 1054 | 148 | 1,21 |

| 3×25 | 30,00 | 1558 | 180 | 0,78 |

| 3×35 | 32,90 | 1997 | 197 | 0,554 |

| 3×50 | 37,70 | 2669 | 226 | 0,386 |

| 3×70 | 43,20 | 3618 | 259 | 0,272 |

| 3×95 | 48,90 | 4702 | 293 | 0,206 |

| 3×120 | 54,00 | 5853 | 324 | 0,161 |

| 4×1 | 13,30 | 248 | 80 | 19,50 |

| 4×1,5 | 14,20 | 289 | 85 | 13,30 |

| 4×2,5 | 16,10 | 383 | 97 | 7,98 |

| 4×4 | 18,00 | 503 | 108 | 4,95 |

| 4×6 | 19,90 | 637 | 119 | 3,30 |

| 4×10 | 24,40 | 992 | 146 | 1,91 |

| 4×16 | 26,80 | 1294 | 161 | 1,21 |

| 4×25 | 33,40 | 1979 | 200 | 0,78 |

| 4×35 | 36,30 | 2495 | 218 | 0,554 |

| 4×50 | 41,70 | 3356 | 250 | 0,386 |

| 4×70 | 48,40 | 4674 | 290 | 0,272 |

| 4×95 | 54,60 | 5992 | 328 | 0,206 |

| 4×120 | 60,30 | 7511 | 362 | 0,161 |

| 5×1,5 | 15,30 | 337 | 92 | 13,30 |

| 5×2,5 | 17,40 | 451 | 104 | 7,98 |

| 5×4 | 19,80 | 609 | 119 | 4,95 |

| 5×6 | 21,40 | 758 | 128 | 3,30 |

| 5×10 | 26,30 | 1173 | 158 | 1,91 |

| 5×16 | 39,60 | 1582 | 238 | 1,21 |

| 5×25 | 37,00 | 2430 | 222 | 0,78 |

| 5×35 | 40,00 | 3049 | 240 | 0,554 |

| 5×50 | 46,30 | 4143 | 278 | 0,386 |

| 5×70 | 53,10 | 5740 | 319 | 0,272 |

| 5×95 | 60,20 | 7440 | 361 | 0,206 |

| 7×1,5 | 16,80 | 414 | 101 | 13,30 |

| 7×2,5 | 19,60 | 588 | 118 | 7,98 |

| 7×4 | 22,60 | 811 | 136 | 4,95 |

| 12×1,5 | 20,10 | 591 | 121 | 13,30 |

| 12×2,5 | 23,20 | 815 | 139 | 7,98 |

| 18×1,5 | 23,40 | 815 | 140 | 13,30 |

| 18×2,5 | 27,20 | 1143 | 163 | 7,98 |

| 24×1,5 | 27,10 | 1041 | 163 | 13,3 |

| 24×2,5 | 31,90 | 1507 | 191 | 7,98 |

| 36×1,5 | 31,00 | 1443 | 186 | 13,30 |

| 36×2,5 | 36,50 | 2079 | 219 | 7,98 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees