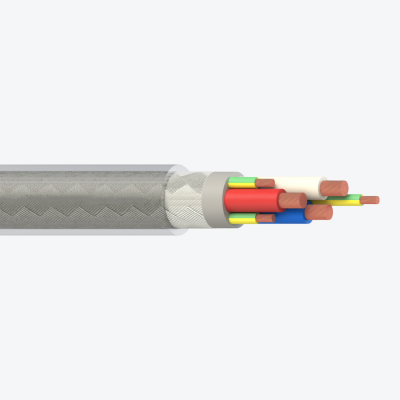

RRF3Z1(AS)-AL Cable Construction

| Conductor | Aluminium conductor (Class 2) according to UNE-EN 60288. |

| Insulation | Cross-linked Polyethylene (XLPE), type DIX 3 according UNE HD 603 and XLPE according IEC 60502. |

| Inner sheath | Cross-linked Polyethylene (XLPE), type DIX 3 according UNE HD 603 and XLPE according IEC 60502. |

| Armour | Corrugated tinned steel tape (F3) |

| Outer sheath | Thermoplastic polyolefin sheath ST8 according to IEC 60502-1 |

| Nominal Voltage | 3/3 kV C.A |

| Voltage Test | 9.500 V C.A (5 minutes) |

| Minimum bending radius | 10 x overall diameter |

| Maximum conductor temperatures | Normal operation 90°C. Short circuit (5sec) 250°C |

RRF3Z1(AS)-AL Cable Application

- Feeder cables: These carry high-current DC power from traction substations to substation nacelles and switch points along the track.

- Parallel cables: These run parallel to the track and regularly feed overhead lines (catenary systems). This reduces voltage drops over long distances, ensuring adequate power even for trains far from the substation.

- Tunnel installations: These are the primary applications. Their stringent fire protection (HFFR) properties make them ideal for confined underground spaces, particularly where passenger safety is paramount.

- Switchgear and substation connections: These connect transformers, rectifiers, and high-voltage switchgear within the substation.

RRF3Z1(AS)-AL Cable Construction Standard

ET-03.354.006.3 Ed.5, IEC-60502-1.

RRF3Z1(AS)-AL Cable Characteristics

- Non-flame propagation according to EN 60332-1-2, IEC 60332-1-2.

- Low halogen content according to EN 60754-2, EN 60754-1, IEC 60754-2, IEC 60754-1.

- Low corrosive gas emission according to EN 60754-2, IEC 60754-2.

- Low smoke emission according to EN 61034-2, IEC 61034-2.

- Fire reaction (CPR) Dca-s2, d2, a2.

- UV resistance (1 cycle) according to UNE 211605.

- Water absorption resistance.

- High cold resistance.

- Impact and rodent resistance.

RRF3Z1(AS)-AL Cable Specification

| Section (mm2) | Resistance at 20 °C (Ohm/km) | Nominal outer diameter (mm) | Weight (kg/m) |

|---|---|---|---|

| 2X35 | 0,868 | 33,6 | 0,969 |

| 2X50 | 0,641 | 35 | 1157 |

| 2X70 | 0,443 | 38,2 | 1407 |

| 2X95 | 0,320 | 41,8 | 1723 |

| 2X120 | 0,253 | 44,6 | 2002 |

| 2X150 | 0,206 | 47,8 | 2314 |

| 3X35 | 0,868 | 35,4 | 1192 |

| 3X50 | 0,641 | 36,9 | 1341 |

| 3X70 | 0,443 | 40,5 | 1660 |

| 3X95 | 0,320 | 44,4 | 2049 |

| 3X120 | 0,253 | 47,4 | 2395 |

| 3X150 | 0,206 | 50,8 | 2776 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees