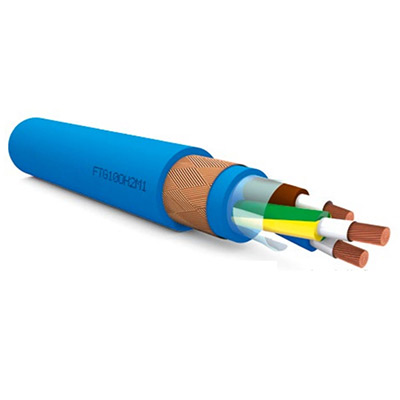

FTG10OH2M1 Cable Construction

| CONDUCTOR | Annealed flexible copper cl.5 |

| CONDUCTOR WRAPPING | Mica glass tape |

| INSULATION | Elastometric compound insulation (G10 quality) |

| TOTAL STRANDING | The cores are stranded together in concentric lay |

| WRAPPING | Polyester tape (if necessary) |

| BINDER | Not hygroscopic filler |

| SCREEN | Type: Wire braid |

| Material: Annealed bare copper | |

| Covered: ≥70% | |

| OUTER SHEATH | LSZH thermoplastic compound type M1 |

FTG10OH2M1 Cable Application

- Industrial automation and process control systems.

- Railway signaling and control systems.

- Control circuits for power plants and substations.

- Fire alarm systems in public buildings (due to the use of low-smoke, zero-halogen materials).

- Connecting control panels to motors, sensors, and actuators in harsh environments.

FTG10OH2M1 Cable Technical Data

| Voltage rating Um | 0,6/1 kV |

| Insulation resistance | ≥100 MΩxkm |

| Dielectric test cond./cond. | 4000 V r.m.s. |

| Maximum operating temperature | +90°C |

| Minimum installation temperature | 0°C |

| Maximum short circuit temperature | +250°C |

| Minimum bending radius | 15 x maximum external diameter |

FTG10OH2M1 Cable Standard

| Conductor characteristic | CEI EN 60228 |

| Construction and material characteristic | CEI EN 20-45 |

| Fire resistance | EN 50200 |

| CEI 20-36/2-1 | |

| Flame retardant | IEC 60332-1-2 |

| EN 50265-2-1 | |

| CEI 20-35/1-1 | |

| Fire retardant cat. C | IEC 60332-3-24 |

| EN 50266-2-4 | |

| CEI 20-22/3-4 | |

| HCI emission | IEC 60754-1 |

| EN 50267-2-1 | |

| CEI 20-37/2-1 | |

| Corrosivity | EN 50267-2-3 |

| CEI 20-37/2-3 | |

| Fume density | IEC 61034-2 |

| EN 50268-2 | |

| CEI 20-37/3-1 | |

| Gas toxicity | CEI 20-37/4-0 |

FTG10OH2M1 Cable Feature

- Exceptional Flexibility: Facilitates installation and routing within complex control panels and industrial machinery.

- High-Temperature and Chemical Resistance: Thermoset insulation ensures reliable operation in high-temperature environments while withstanding exposure to oils, chemicals, and solvents.

- Superior Electromagnetic Shielding: Integral copper braid effectively shields sensitive signals and control circuits from electrical noise interference, preventing automation system failures.

- Enhanced Mechanical Protection: The combination of an inner sheath and robust copper braid provides superior resistance to crushing, abrasion, and cutting.

- Maximum Fire Safety: This is a key safety feature. In the event of fire: Generates minimal smoke, ensuring clear visibility for evacuation. Does not release toxic/halogen gases, preventing the formation of corrosive acids that harm personnel and equipment.

FTG10OH2M1 Cable Specification

| Size | Approx. conduct. Ø | Average insulation thickness | Average sheath thickness | Nominal Outer Ø | Nominal cable weight | Max electrical resistan- ce at 20° C |

| n° x mm2 | mm | mm | mm | mm | kg/km | Ω/km |

| 2 x 1,5 | 1,5 | 1,0 | 1,8 | 16,7 | 230 | 13,3 |

| 2 x 2,5 | 2,0 | 1,0 | 1,8 | 18,1 | 270 | 7,98 |

| 2 x 4 | 2,5 | 1,0 | 1,8 | 18,9 | 320 | 4,95 |

| 2 x 6 | 3,0 | 1,0 | 1,8 | 20,2 | 395 | 3,30 |

| 2 x 10 | 4,0 | 1,0 | 1,8 | 22,4 | 510 | 1,91 |

| 2 x 16 | 5,0 | 1,0 | 1,8 | 24,0 | 805 | 1,21 |

| 2 x 25 | 6,2 | 1,2 | 2,0 | 27,0 | 1.15 | 0,798 |

| 2 x 35 | 7,4 | 1,2 | 2,0 | 28,9 | 1.465 | 0,554 |

| 2 x 50 | 11,7 | 1,4 | 1,9 | 32,6 | 1.99 | 0,386 |

| 2 x 70 | 13,3 | 1,4 | 2,0 | 37,7 | 3.05 | 0,272 |

| 2 x 95 | 15,3 | 1,6 | 2,1 | 41,6 | 3.93 | 0,206 |

| 2 x 120 | 16,7 | 1,6 | 2,1 | 45,7 | 4.87 | 0,161 |

| 2 x 150 | 18,8 | 1,8 | 2,4 | 50,0 | 6.03 | 0,129 |

| 3 x 1,5 | 1,5 | 1,0 | 1,8 | 17,4 | 328 | 13,3 |

| 3 x 2,5 | 2,0 | 1,0 | 1,8 | 18,3 | 393 | 7,98 |

| 3 x 4 | 2,5 | 1,0 | 1,8 | 19,6 | 480 | 4,95 |

| 3 x 6 | 3,0 | 1,0 | 1,8 | 21,0 | 578 | 3,30 |

| 3 x 10 | 4,0 | 1,0 | 1,8 | 24,0 | 829 | 1,91 |

| 3 x 16 | 5,0 | 1,0 | 2,0 | 25,8 | 1.094 | 1,21 |

| 3 x 25 | 6,2 | 1,2 | 2,0 | 29,2 | 1.595 | 0,798 |

| 3 x 35 | 7,4 | 1,2 | 2,0 | 32,2 | 1.352 | 0,554 |

| 3 x 50 | 8,9 | 1,4 | 2,1 | 37,0 | 2.828 | 0,386 |

| 3 x 70 | 10,5 | 1,4 | 2,1 | 41,1 | 3.76 | 0,272 |

| 3 x 95 | 12,2 | 1,6 | 2,2 | 46,1 | 4.957 | 0,206 |

| 3 x 120 | 13,8 | 1,6 | 2,3 | 50,7 | 6.035 | 0,161 |

| 3 x 150 | 15,4 | 1,8 | 2,5 | 55,3 | 7.433 | 0,129 |

| 3 x 185 | 16,9 | 2 | 2,6 | 60,2 | 8.971 | 0,106 |

| 3 x 240 | 19,5 | 2,2 | 2,9 | 68,9 | 11.696 | 0,0801 |

| 3 x 300 | 22,0 | 2,4 | 3,1 | 75,3 | 0,0641 | |

| 4 x 1,5 | 1,5 | 1,0 | 1,8 | 18,0 | 300 | 13,3 |

| 4 x 2,5 | 2,0 | 1,0 | 1,8 | 20,2 | 372 | 7,98 |

| 4 x 4 | 2,5 | 1,0 | 1,8 | 21,1 | 460 | 4,95 |

| 4 x 6 | 3,0 | 1,0 | 1,8 | 22,2 | 585 | 3,30 |

| 4 x 10 | 4,0 | 1,0 | 2,0 | 25,4 | 890 | 1,91 |

| 4 x 16 | 5,0 | 1,0 | 2,0 | 29,1 | 1.25 | 1,21 |

| 4 x 25 | 6,2 | 1,2 | 2,0 | 33,1 | 1.78 | 0,780 |

| 3 x 35 + 25 | 7,4/6,2 | 1,2 | 2,0 | 35,4 | 2.27 | 0,554/0,780 |

| 3 x 50 + 25 | 8,9/6,2 | 1,4 | 2,0 | 38,9 | 3 | 0,386/0,780 |

| 3 x 70 + 35 | 10,5/7,4 | 1,4 | 2,1 | 43,5 | 4.08 | 0,272/0,554 |

| 3 x 95 + 50 | 12,2/8,9 | 1,6 | 2,3 | 49,1 | 5.46 | 0,206/0,386 |

| 3 x 120 + 70 | 13,8/10,5 | 1,6 | 2,4 | 55,4 | 7.01 | 0,161/0,272 |

| 3 x 150 + 95 | 15,4/12,2 | 1,8 | 2,6 | 60,5 | 8.715 | 0,129/,0206 |

| 3 x 185 + 95 | 16,9/12,2 | 2,0 | 2,7 | 64,1 | 10.08 | 0,106/0,206 |

| 3 x 240 +150 | 19,5/15,4 | 2,2 | 3,0 | 63,9 | 13.55 | 0,0801/0,129 |

| 5G1,5 | 1,5 | 1,0 | 1,8 | 20,1 | 360 | 13,3 |

| 5G2,5 | 2,0 | 1,0 | 1,8 | 21,4 | 450 | 7,98 |

| 5G4 | 2,5 | 1,0 | 1,8 | 22,2 | 570 | 4,95 |

| 5G6 | 3,0 | 1,0 | 1,8 | 23,9 | 730 | 3,30 |

| 5G10 | 4,0 | 1,0 | 2,0 | 28,1 | 1.14 | 1,91 |

| 5G16 | 5,0 | 1,0 | 2,0 | 32,3 | 1.56 | 1,21 |

| 5G25 | 6,2 | 1,2 | 2,0 | 36,2 | 2.34 | 0,780 |

| 5G35 | 7,4 | 1,2 | 2,2 | 36,9 | 0,554 | |

| 5G50 | 8,9 | 1,4 | 2,3 | 41,2 | 0,386 | |

| 5G1,5 | 1,5 | 1,0 | 13,3 | |||

| 7G1,5 | 1,5 | 1,0 | 1,8 | 21,5 | 480 | 13,3 |

| 10G1,5 | 1,5 | 1,0 | 2,0 | 23,8 | 640 | 13,4 |

| 12G1,5 | 1,5 | 1,0 | 2,0 | 25,9 | 740 | 13,4 |

| 16G1,5 | 1,5 | 1,0 | 2,0 | 28,3 | 1 | 13,4 |

| 19G1,5 | 1,5 | 1,0 | 2,0 | 29,5 | 1.13 | 13,4 |

| 24G1,5 | 1,5 | 1,0 | 2,0 | 33,8 | 1.39 | 13,5 |

| 7G2,5 | 2,0 | 1,0 | 1,8 | 22,3 | 600 | 7,98 |

| 10G2,5 | 2,0 | 1,0 | 2,0 | 25,5 | 800 | 8,06 |

| 12G2,5 | 2,0 | 1,0 | 2,0 | 27,8 | 930 | 8,06 |

| 16G2,5 | 2,0 | 1,0 | 2,0 | 31,5 | 1.3 | 8,06 |

| 19G2,5 | 2,0 | 1,0 | 2,0 | 32,9 | 1.47 | 8,06 |

| 24G2,5 | 2,0 | 1,0 | 2,2 | 37,2 | 1.83 | 8,10 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees