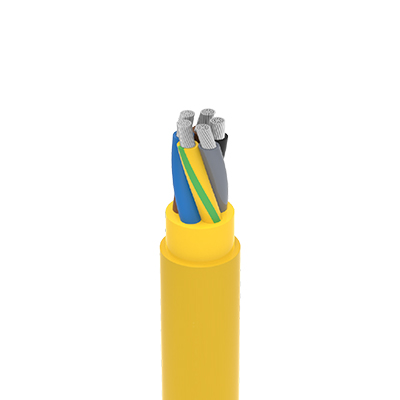

Type 260 Armoured Mining Cable Construction

| Conductor | Flexible stranded tinned annealed copper |

| Conductor Screen | Semiconductive compound for cables having a voltage rating of 3.3/3.3kV and above |

| Insulation | EPR (Ethylene-Propylene Compound) |

| Insulation Screen | Semiconductive elastomer |

| Screen / Earth Conductor | Tinned copper braid interwove with polyester yarn |

| Cradle Separator | Semiconductive PCP (Polychloroprene) |

| Interstitial Pilot | EPR (Ethylene-Propylene Compound) covered flexible stranded tinned copper |

| Inner Sheath | PCP (Polychloroprene) |

| Armour | SWA (Pliable Galvanised Steel Wires) |

| Sheath | PCP (Polychloroprene) - Heavy Duty (CPE/CSP sheath can be offered upon request) |

Type 260 Armoured Mining Cable Application

- Underground Mining: Continuous miners, mine cars, roof bolting machines, feeders and crushers, and longwall mining units.

- Open-Pit Mining: Grab excavators, excavators, drilling rigs, and heavy mobile equipment in open-pit mines.

- Tunneling and Heavy Construction: Any application requiring robust and flexible power transmission for mobile equipment in demanding environments.

Type 260 Armoured Mining Cable Technical Data

- Voltage Rating

- 1.1kV – Type 260.1

- 3.3kV – Type 260.3

- 6.6kV – Type 260.6

- 11kV – Type 260.11

Type 260 Armoured Mining Cable Standard

- AS/NZS 1802:2003, AS/NZS 1125, AS/NZS 3808, AS/NZS 5000.1

Type 260 Armoured Mining Cable Feature

- Ultimate Flexibility

- Compression and Impact Resistance

- Abrasion and Tear Resistance

- Flame Retardancy

- Moisture Resistance and Chemical Resistance

- Superior Electrical Properties

- Durability and Long Service Life

Type 260 Armoured Mining Cable Specification

| NO. OF CORES | NOMINAL CONDUCTOR AREA | STRAND SIZE | NOMINAL INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | NOMINAL ARMOUR SIZE | NOMINAL SHEATH THICKNESS | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm2 | No/mm | mm | STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | No/mm | INNER | OUTER | mm | kg/100m | |

| No/mm | mm2 | No/mm | mm | mm | mm | |||||||

| Type 260.1 | ||||||||||||

| 3 | 6 | 84/0.30 | 1.5 | 7/0.25 | 7.2 | 18/0.30 | 1 | 7/0.45 | 2 | 3.8 | 36.9 | 230 |

| 3 | 10 | 77/0.40 | 1.5 | 7/0.25 | 8.6 | 27/0.30 | 1 | 7/0.45 | 2 | 3.8 | 39.5 | 265 |

| 3 | 16 | 126/0.40 | 1.6 | 7/0.25 | 9.6 | 42/0.30 | 1 | 7/0.90 | 2.5 | 4 | 46.5 | 410 |

| 3 | 25 | 209/0.40 | 1.6 | 7/0.25 | 11.3 | 66/0.30 | 1.2 | 7/0.90 | 2.5 | 4.3 | 50.4 | 495 |

| 3 | 35 | 285/0.40 | 1.6 | 7/0.25 | 12.4 | 90/0.30 | 1.2 | 7/0.90 | 2.5 | 4.6 | 53.8 | 576 |

| 3 | 50 | 380/0.40 | 1.7 | 7/0.25 | 14.1 | 120/0.30 | 1.2 | 7/0.90 | 2.5 | 5 | 58.4 | 679 |

| 3 | 70 | 203/0.67 | 1.8 | 7/0.25 | 16.5 | 39/0.67 | 1.2 | 7/0.90 | 2.5 | 5.4 | 64.6 | 837 |

| 3 | 95 | 259/0.67 | 2 | 7/0.25 | 18.2 | 39/0.67 | 1.2 | 7/0.90 | 3.5 | 6 | 71.4 | 1003 |

| 3 | 120 | 336/0.67 | 2.1 | 7/0.25 | 20.3 | 42/0.67 | 1.4 | 7/0.90 | 3.5 | 6.4 | 77.2 | 1176 |

| 3 | 150 | 427/0.67 | 2.3 | 7/0.25 | 22.3 | 54/0.67 | 1.4 | 7/0.90 | 3.5 | 6.9 | 83 | 1372 |

| 3 | 185 | 518/0.67 | 2.5 | 7/0.30 | 30.2 | 63/0.67 | 1.4 | 7/0.90 | 3.5 | 7.4 | 90 | 1610 |

| 3 | 240 | 672/0.67 | 2.8 | 7/0.30 | 33.6 | 77/0.67 | 1.6 | 7/1.25 | 4.5 | 8.2 | 103 | 2150 |

| 3 | 300 | 854/0.67 | 3 | 7/0.40 | 50.1 | 98/0.67 | 1.6 | 7/1.25 | 4.5 | 8.8 | 112.1 | 2590 |

| Type 260.3 | ||||||||||||

| 3 | 126/0.40 | 3 | 7/0.25 | 13.1 | 42/0.30 | 1.4 | 7/0.90 | 2.5 | 5.3 | 56.9 | 566 | |

| 3 | 209/0.40 | 3 | 7/0.25 | 14.8 | 66/0.30 | 1.4 | 7/0.90 | 2.5 | 5.6 | 60.8 | 661 | |

| 3 | 285/0.40 | 3 | 7/0.25 | 15.8 | 90/0.30 | 1.4 | 7/0.90 | 3.5 | 5.9 | 66.3 | 779 | |

| 3 | 380/0.40 | 3 | 7/0.25 | 17.2 | 120/0.30 | 1.4 | 7/0.90 | 3.5 | 6.3 | 70.4 | 886 | |

| 3 | 203/0.67 | 3 | 7/0.25 | 18.6 | 39/0.67 | 1.4 | 7/0.90 | 3.5 | 6.6 | 75.3 | 1044 | |

| 3 | 259/0.67 | 3 | 7/0.25 | 20.3 | 39/0.67 | 1.4 | 7/0.90 | 3.5 | 7.1 | 78.9 | 1156 | |

| 3 | 336/0.67 | 3 | 7/0.30 | 27.2 | 42/0.67 | 1.6 | 7/0.90 | 3.5 | 7.4 | 84.7 | 1350 | |

| 3 | 427/0.67 | 3 | 7/0.40 | 39.6 | 54/0.67 | 1.6 | 7/1.25 | 4.5 | 7.8 | 95 | 1779 | |

| 3 | 518/0.67 | 3 | 7/0.40 | 42.2 | 63/0.67 | 1.8 | 7/1.25 | 4.5 | 8.2 | 100.4 | 1990 | |

| 3 | 672/0.67 | 3 | 7/0.40 | 46.6 | 77/0.67 | 1.8 | 7/1.25 | 4.5 | 8.8 | 107.3 | 2300 | |

| 3 | 854/0.67 | 3 | 7/0.50 | 63.2 | 98/0.67 | 1.8 | 7/1.25 | 4.5 | 9.4 | 115.4 | 2710 | |

| Type 260.6 | ||||||||||||

| 3 | 16 | 126/0.40 | 5 | 7/0.25 | 17.2 | 42/0.30 | 1.4 | 7/0.90 | 3.5 | 6.4 | 70.1 | 796 |

| 3 | 25 | 209/0.40 | 5 | 7/0.25 | 18.6 | 66/0.30 | 1.4 | 7/0.90 | 3.5 | 6.7 | 74 | 897 |

| 3 | 35 | 285/0.40 | 5 | 7/0.25 | 18.6 | 90/0.30 | 1.6 | 7/0.90 | 3.5 | 7 | 77.4 | 990 |

| 3 | 50 | 380/0.40 | 5 | 7/0.25 | 21.3 | 120/0.30 | 1.6 | 7/0.90 | 3.5 | 7.3 | 81.2 | 1102 |

| 3 | 70 | 203/0.67 | 5 | 7/0.25 | 23.4 | 39/0.67 | 1.6 | 7/1.25 | 4.5 | 7.7 | 90.7 | 1456 |

| 3 | 95 | 259/0.67 | 5 | 7/0.30 | 29.2 | 39/0.67 | 1.6 | 7/1.25 | 4.5 | 8.1 | 94.8 | 1610 |

| 3 | 120 | 336/0.67 | 5 | 7/0.30 | 31.7 | 42/0.67 | 1.8 | 7/1.25 | 4.5 | 8.5 | 100.2 | 1807 |

| 3 | 150 | 427/0.67 | 5 | 7/0.40 | 45.7 | 54/0.67 | 1.8 | 7/1.25 | 4.5 | 8.9 | 106.2 | 2080 |

| 3 | 185 | 518/0.67 | 5 | 7/0.40 | 48.4 | 63/0.67 | 1.8 | 7/1.25 | 4.5 | 9.3 | 111.5 | 2300 |

| 3 | 240 | 672/0.67 | 5 | 7/0.40 | 52.8 | 77/0.67 | 1.8 | 7/1.25 | 4.5 | 9.9 | 118.4 | 2630 |

| 3 | 300 | 854/0.67 | 5 | 7/0.50 | 71.5 | 98/0.67 | 1.8 | 7/1.25 | 4.5 | 10.4 | 126.3 | 3060 |

| Type 260.11 | ||||||||||||

| 3 | 25 | 209/0.40 | 7.6 | 7/0.25 | 23.7 | 66/0.30 | 2 | 7/1.25 | 4.5 | 8.1 | 92.7 | 1380 |

| 3 | 35 | 285/0.40 | 7.6 | 7/0.30 | 30.2 | 90/0.30 | 2 | 7/1.25 | 4.5 | 8.4 | 96.7 | 1528 |

| 3 | 50 | 380/0.40 | 7.6 | 7/0.30 | 31.7 | 120/0.30 | 2 | 7/1.25 | 4.5 | 8.7 | 100.6 | 1664 |

| 3 | 70 | 203/0.67 | 7.6 | 7/0.30 | 34.1 | 39/0.67 | 2 | 7/1.25 | 4.5 | 9.1 | 105.8 | 1867 |

| 3 | 95 | 259/0.67 | 7.6 | 7/0.40 | 47.5 | 39/0.67 | 2 | 7/1.25 | 4.5 | 9.6 | 110.7 | 2080 |

| 3 | 120 | 336/0.67 | 7.6 | 7/0.40 | 51 | 42/0.67 | 2.2 | 7/1.25 | 4.5 | 9.9 | 115.8 | 2290 |

| 3 | 150 | 427/0.67 | 7.6 | 7/0.40 | 53.7 | 54/0.67 | 2.2 | 7/1.25 | 4.5 | 10.3 | 120.5 | 2510 |

| 3 | 185 | 518/0.67 | 7.6 | 7/0.40 | 57.2 | 63/0.67 | 2.2 | 7/1.25 | 4.5 | 10.7 | 125.9 | 2750 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees