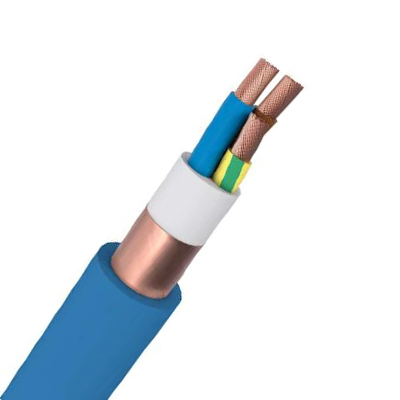

NF C 33-226 Cable Construction

| 12/20(24) kV | 18/30(36) kV | |

|---|---|---|

| Conductor | Aluminium | Aluminium |

| Conductor flexibility | Stranded class 2 | Stranded class 2 |

| Conductor shape | Circular stranded (RM) | Circular |

| Material of the inner semi-conductor | XLPE-SC | XLPE-SC |

| Insulation | XLPE (chemical) | XLPE (chemical) |

| Material of the external semi-conductor | Extruded strippable grooved elastomer | Extruded strippable grooved elastomer |

| Material used for longitudinal water tightness | Swelling powder | Swelling powder |

| Screen Longitudinal | aluminium tape | aluminium tape |

| Outer sheath | PE | PE |

NF C 33-226 Cable Application

These power cables are typically used in public distribution networks. Additional applications include:

- Underground distribution networks: Directly buried underground or installed in conduits.

- Industrial sites: Power distribution within large factories, refineries, and data centers.

- Infrastructure projects: Airports, railways, tunnels, and hospitals.

- Renewable energy: Connecting wind turbines and solar power plants to the grid.

- Interconnection between substations.

NF C 33-226 Cable Characteristics

| 12/20 kV | 18 / 30 (36) kV | |

|---|---|---|

| Electrical characteristics | ||

| Rated Voltage Uo/U (Um) | 12/20 kV | 18 / 30 (36) kV |

| Mechanical characteristics | ||

| Mechanical resistance to impacts | - | Good |

| Cable flexibility | Rigid | Rigid |

| Usage characteristics | ||

| Flame retardant | C2, NF C 32-070 | C2, NF C 32-070 |

| Weather resistance | AN3 / AF2 | Good |

| Chemical resistance | - | Accidental |

| Water proof | AD8 | Intermittent |

| Bending factor when laying | - | 15 (xD) |

| Max. conductor temperature in service | - | 90 °C |

NF C 33-226 Cable Standard

Product NF C33-226

- 12/20(24) kV NF C 33-226 Cable Specification

- 18/30(36) kV NF C 33-226 Cable Specification

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA | NOMINAL SCREEN CROSS SECTIONAL AREA | NOMINAL CONDUCTOR SCREEN THICKNESS | NOMINAL INSULATION THICKNESS | NOMINAL INSULATION SCREEN THICKNESS | NOMINAL SHEATH THICKNESS | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT |

|---|---|---|---|---|---|---|---|---|

| mm2 | mm2 | mm | mm | mm | mm | mm | kg/km | |

| 1 | 50 | 15 | 0.6 | 4.5 | 0.7 | 1.7 | 25.8 | 614 |

| 1 | 70 | 17 | 0.6 | 4.5 | 0.7 | 1.8 | 27.6 | 731 |

| 1 | 95 | 18 | 0.6 | 4.5 | 0.7 | 1.8 | 29.1 | 833 |

| 1 | 120 | 19 | 0.6 | 4.5 | 0.7 | 1.9 | 30.7 | 953 |

| 1 | 150 | 20 | 0.6 | 4.5 | 0.7 | 1.9 | 32.9 | 1090 |

| 1 | 185 | 21 | 0.6 | 4.5 | 0.7 | 2 | 34 | 1212 |

| 1 | 240 | 22 | 0.6 | 4.5 | 0.7 | 2.1 | 36.6 | 1440 |

| 1 | 300 | 24 | 0.6 | 4.5 | 0.7 | 2.1 | 39 | 1674 |

| 1 | 400 | 26 | 0.6 | 4.5 | 0.7 | 2.3 | 41.9 | 2027 |

| 1 | 500 | 28 | 0.6 | 4.5 | 0.7 | 2.4 | 45.1 | 2411 |

| 1 | 630 | 31 | 0.7 | 4.5 | 0.7 | 2.5 | 50 | 3010 |

| 1 | 800 | 34 | 0.7 | 4.5 | 0.7 | 2.6 | 55 | 3718 |

| 3x1 | 50 | 15 | 0.6 | 4.5 | 0.7 | 2.1 | 55.7 | 1845 |

| 3x1 | 70 | 17 | 0.6 | 4.5 | 0.7 | 1.8 | 59.6 | 2197 |

| 3x1 | 95 | 18 | 0.6 | 4.5 | 0.7 | 1.8 | 62.9 | 2509 |

| 3x1 | 120 | 19 | 0.6 | 4.5 | 0.7 | 1.9 | 66.3 | 2872 |

| 3x1 | 150 | 20 | 0.6 | 4.5 | 0.7 | 1.9 | 71.1 | 3287 |

| 3x1 | 185 | 21 | 0.6 | 4.5 | 0.7 | 2 | 73.4 | 3659 |

| 3x1 | 240 | 22 | 0.6 | 4.5 | 0.7 | 2.1 | 79.1 | 4349 |

| 3x1 | 300 | 24 | 0.6 | 4.5 | 0.7 | 2.1 | 84.2 | 5057 |

| 3x1 | 400 | 26 | 0.6 | 4.5 | 0.7 | 2.3 | 90.5 | 6132 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA | NOMINAL SCREEN CROSS SECTIONAL AREA | NOMINAL CONDUCTOR SCREEN THICKNESS | NOMINAL INSULATION THICKNESS | NOMINAL INSULATION SCREEN THICKNESS | NOMINAL SHEATH THICKNESS | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT |

|---|---|---|---|---|---|---|---|---|

| mm2 | mm2 | mm | mm | mm | mm | mm | kg/km | |

| 1 | 50 | 18 | 0.6 | 6.7 | 0.7 | 1.9 | 30.6 | 819 |

| 1 | 70 | 20 | 0.6 | 6.7 | 0.7 | 1.9 | 32.2 | 939 |

| 1 | 95 | 21 | 0.6 | 6.7 | 0.7 | 2 | 33.9 | 1062 |

| 1 | 120 | 22 | 0.6 | 6.7 | 0.7 | 2.1 | 35.5 | 1193 |

| 1 | 150 | 23 | 0.6 | 6.7 | 0.7 | 2.1 | 37.7 | 1345 |

| 1 | 185 | 24 | 0.6 | 6.7 | 0.7 | 2.2 | 38.8 | 1477 |

| 1 | 240 | 25 | 0.6 | 6.7 | 0.7 | 2.2 | 41.2 | 1709 |

| 1 | 300 | 27 | 0.6 | 6.7 | 0.7 | 2.3 | 43.8 | 1972 |

| 1 | 400 | 29 | 0.6 | 6.7 | 0.7 | 2.4 | 46.5 | 2334 |

| 1 | 500 | 31 | 0.6 | 6.7 | 0.7 | 2.5 | 49.7 | 2741 |

| 1 | 630 | 34 | 0.7 | 6.7 | 0.7 | 2.6 | 54.6 | 3372 |

| 1 | 800 | 37 | 0.7 | 6.7 | 0.7 | 2.8 | 59.8 | 4132 |

| 3x1 | 50 | 18 | 0.6 | 6.7 | 0.7 | 1.9 | 66.1 | 2469 |

| 3x1 | 70 | 20 | 0.6 | 6.7 | 0.7 | 1.9 | 69.6 | 2829 |

| 3x1 | 95 | 21 | 0.6 | 6.7 | 0.7 | 2 | 73.2 | 3203 |

| 3x1 | 120 | 22 | 0.6 | 6.7 | 0.7 | 2.1 | 76.7 | 3602 |

| 3x1 | 150 | 23 | 0.6 | 6.7 | 0.7 | 2.1 | 81.4 | 4064 |

| 3x1 | 185 | 24 | 0.6 | 6.7 | 0.7 | 2.2 | 83.8 | 4459 |

| 3x1 | 240 | 25 | 0.6 | 6.7 | 0.7 | 2.2 | 89 | 5166 |

| 3x1 | 300 | 27 | 0.6 | 6.7 | 0.7 | 2.3 | 94.6 | 5965 |

| 3x1 | 400 | 29 | 0.6 | 6.7 | 0.7 | 2.4 | 100.4 | 7063 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees