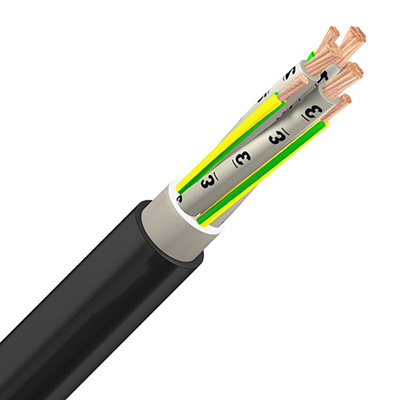

(N)SHOEU Cable Construction

| Conductor | Bare electrolytic copper, finely stranded (class 5) |

| Insulation | PROTOLON, Basic material: EPR, Compound type: Special compound better 3GI3 |

| Core identification | Light gray with black digits |

| Screen | In case of concentric screen (KON types only): closed layer of copper wire spinning over core assembly |

| Inner sheath | Basic material: EPR, Compound type: Special compound |

| Outer sheath | Basic material: Chlorinated rubber, Compound type: Special compound, 5GM5 Colour: yellow |

(N)SHOEU Cable Application

(N)SHOEU Cable exhibits excellent resistance to grease and oil and is suitable for installation in dry, damp, humid, and hazardous environments. It can also be permanently submerged in fresh water, salt water, rainwater, oily water, and wastewater contaminated with sewage. Due to these characteristics, the cable can be applied in the following scenarios:

- Conveyor belts (also suitable for mobile units)

- Longwall shearers and continuous miners

- Connections between shuttle cars and loaders (LHD)

- Roof bolting machines

- Ventilation fans

- Connecting submersible pump units

- Providing temporary lighting and power supply for work surfaces

(N)SHOEU Cable Technical Data

| Rated voltage | 0.6/1 kV (600/1000V) |

| Max. permissible operating voltage AC | 0.7/1.2 kV |

| Max. permissible operating voltage DC | 0.9/1.8 kV |

| AC test voltage - main cores | 3,5 kV ( 5 Min.) |

| AC test voltage - control cores | 2 kV |

| Max. operating temperature of the conductor | 90 °C |

| Max. short circuit temperature of the conductor | 250 °C |

| Max. permissible water temperature | 40 °C (At higher water temperatures, a shortened cable service life is to be expected) |

| Ambient temperature for fixed installation | min -40 °C ; max +80 °C |

| Ambient temperature in fully flexible operation | min -25 °C ; max +60 °C |

| Max. tensile load on the conductor | 15 N/mm² |

| Torsional stress +/- | 100 °/m |

| Bending radii min. | Acc. to DIN VDE 0298 part 3 |

| Travel speed | Max. speed on rewinding with drum car: 60 m/min |

(N)SHOEU Cable Standard

- Based on DIN VDE 0250 part 812

(N)SHOEU Cable Feature

- Durability: The cable is designed to withstand high mechanical stress, abrasion, cutting, and tearing.

- Environmental Resistance: Features flame-retardant properties, resistance to UV radiation, oil, and grease corrosion. Capable of permanent submersion in various water bodies (including fresh water, salt water, and sewage) at depths up to 100 meters.

- Versatility: Suitable for flexible cabling in both dry and wet environments (such as trailing cables) and fixed installation scenarios.

- (N)SHOEU-O Cable Specification

- (N)SHOEU-J Cable Specification

| Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Inner Sheath | Thickness of Outer Sheath | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|---|---|---|

| No.×mm² | mm | mm | mm | mm | mm | kg/km |

| 5×1.5 | 0.6 | 0.8 | 1.2 | 12 | 14 | 240 |

| 5×2.5 | 0.7 | 0.9 | 1.3 | 13 | 14.8 | 305 |

| 5×4 | 0.8 | 0.9 | 1.4 | 14.8 | 17 | 440 |

| 5×6 | 0.8 | 1 | 1.6 | 17 | 19 | 580 |

| 5×10 | 1 | 1 | 1.6 | 20 | 23 | 870 |

| 5×16 | 1 | 1.2 | 1.8 | 23.8 | 26.8 | 1280 |

| 5×25 | 1 | 1.3 | 2.3 | 29.5 | 32.5 | 1950 |

| 2×1.5 | 0.6 | 0.8 | 1.2 | 9.8 | 11.8 | 155 |

| 7×1.5 | 0.6 | 0.9 | 1.4 | 13 | 14.6 | 295 |

| 8×1.5 | 0.6 | 0.9 | 1.4 | 14 | 15.6 | 320 |

| 10×1.5 | 0.6 | 1 | 1.6 | 15.5 | 17.5 | 390 |

| 12×1.5 | 0.6 | 1 | 1.6 | 16.5 | 18.5 | 445 |

| 2×2.5 | 0.7 | 0.8 | 1.2 | 10.8 | 12.8 | 195 |

| 4×2.5 | 0.7 | 0.9 | 1.4 | 11.7 | 13.7 | 290 |

| 7×2.5 | 0.7 | 0.9 | 1.4 | 15 | 17 | 410 |

| 8×2.5 | 0.7 | 0.9 | 1.4 | 16 | 19 | 430 |

| 10×2.5 | 0.7 | 1 | 1.6 | 18 | 20.5 | 520 |

| 12×2.5 | 0.7 | 1 | 1.6 | 18.5 | 21.5 | 580 |

| 18×2.5 | 0.7 | 1 | 1.6 | 21.5 | 24.5 | 835 |

| 24×2.5 | 0.7 | 1.2 | 1.8 | 25.5 | 28.5 | 895 |

| 2×4 | 0.8 | 0.9 | 1.2 | 12 | 13.6 | 250 |

| 12×4 | 0.8 | 1.2 | 1.8 | 25 | 28 | 990 |

| 1×16 | 1 | - | 1.4 | 9.6 | 11.2 | 215 |

| 1×25 | 1 | - | 1.7 | 11.2 | 13.2 | 325 |

| 1×35 | 1 | - | 1.8 | 12.6 | 14.6 | 430 |

| 1×50 | 1.1 | - | 2 | 14.6 | 16.6 | 610 |

| 1×70 | 1.1 | - | 2.2 | 16.6 | 18.6 | 825 |

| 1×95 | 1.2 | - | 2.3 | 18.9 | 20.9 | 1070 |

| 1×120 | 1.2 | - | 2.4 | 20.8 | 22.8 | 1300 |

| 1×150 | 1.3 | - | 2.5 | 23 | 25 | 1610 |

| 1×185 | 1.4 | - | 2.6 | 24.9 | 27.9 | 2000 |

| 1×240 | 1.5 | - | 2.8 | 28.2 | 31.2 | 2500 |

| 1×300 | 1.8 | - | 3.3 | 31.8 | 34.8 | 3200 |

| 3×2.5 | 0.7 | 0.8 | 1.2 | 11.3 | 12.9 | 240 |

| 3×4 | 0.8 | 0.9 | 1.3 | 12.5 | 14.1 | 295 |

| 3×6 | 0.8 | 1 | 1.4 | 13.9 | 15.5 | 370 |

| 3×10 | 1 | 1 | 1.4 | 16.8 | 18.8 | 570 |

| 3×16 | 1 | 1 | 1.6 | 19 | 22 | 770 |

| 3×25 | 1 | 1.2 | 2 | 23.5 | 26.5 | 1200 |

| 3×35 | 1.1 | 1.3 | 2.2 | 27.5 | 30.5 | 1570 |

| 3×50 | 1.1 | 1.5 | 2.6 | 31.5 | 35.5 | 2200 |

| 3×70 | 1.1 | 1.5 | 2.6 | 36 | 40 | 2910 |

| 3×95 | 1.2 | 1.7 | 2.8 | 41 | 45 | 3780 |

| 3×120 | 1.2 | 1.8 | 3 | 45 | 49 | 4700 |

| 3×150 | 1.3 | 1.7 | 2.8 | 49 | 53 | 5650 |

| 3×185 | 1.4 | 2.2 | 3.4 | 55 | 59 | 7050 |

| Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Inner Sheath | Thickness of Outer Sheath | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|---|---|---|

| No.×mm² | mm | mm | mm | mm | mm | kg/km |

| 3×1.0 | 0.6 | 0.8 | 1.2 | 9.2 | 9.6 | 160 |

| 3×1.5 | 0.6 | 0.8 | 1.2 | 10.4 | 12 | 180 |

| 3×2.5 | 0.7 | 0.8 | 1.2 | 11.3 | 12.9 | 240 |

| 3×4 | 0.8 | 0.9 | 1.3 | 12.5 | 14.1 | 295 |

| 3×6 | 0.8 | 1 | 1.4 | 13.9 | 15.5 | 370 |

| 3×10 | 1 | 1 | 1.4 | 16.8 | 18.8 | 570 |

| 3x50+3x25/3 | 1.1 | 1.4 | 2.5 | 31.5 | 34.5 | 2500 |

| 3x70+3x35/3 | 1.1 | 1.4 | 2.5 | 36.2 | 39.2 | 3400 |

| 3x95+3x50/3 | 1.2 | 1.7 | 2.8 | 42 | 45 | 4475 |

| 3x120+3x70/3 | 1.2 | 2 | 3 | 46 | 49 | 5400 |

| 4×1.5 | 0.6 | 0.8 | 1.2 | 10.7 | 13 | 210 |

| 4×2.5 | 0.7 | 0.9 | 1.4 | 11.7 | 13.7 | 260 |

| 4×4 | 0.8 | 0.9 | 1.4 | 13.7 | 15.7 | 350 |

| 4×6 | 0.8 | 1 | 1.4 | 15.2 | 17.2 | 485 |

| 4×10 | 1 | 1 | 1.6 | 19 | 21 | 690 |

| 4×16 | 1 | 1.2 | 1.8 | 22 | 24 | 1090 |

| 4×25 | 1 | 1.3 | 2.2 | 26.5 | 29.5 | 1600 |

| 4×35 | 1 | 1.3 | 2.3 | 30 | 33 | 2090 |

| 4×50 | 1.1 | 1.5 | 2.6 | 34.5 | 38.5 | 2700 |

| 4×70 | 1.1 | 1.5 | 2.6 | 39.5 | 43.5 | 3620 |

| 4×95 | 1.2 | 1.7 | 2.8 | 45 | 49 | 4710 |

| 4×120 | 1.2 | 2 | 3.3 | 51 | 55 | 6020 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

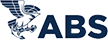

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees