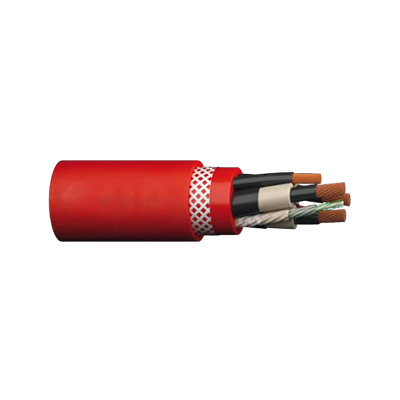

R-(N)TSCGEWÖU Cable Construction

| Conductors | Flexible stranded annealed tin coated or bare copper conductor class 5 to IEC 60228 |

| Separator | Wrap of semi-conductive tape between the power conductor and insulation and between earth conductor and semi-conductive layer |

| Conductor screen | Semi-conductive layer of special rubber |

| Insulation screen | Semi-conductive. special strippable layer over insulation of power cores. Maximum resistivity of semi-conductive layers -200 [Ω x m] |

| Earth conductor | Tin coated or bare copper conductor class 5 to IEC 60228 with extruded special semi-conductive rubber compound |

| Core arrangement | Power cores and earth conductor split into 3 parts laid up around conductive filler in the centre. Antiadhesion graphite over assembled cores |

| Inner sheath | A special synthetic thermosetting compound type 5GM3 acc. to DIN VDE 0207/21 |

| Anti-torsion braid | Braid of polyamide threads between internal and outer layer of sheath |

| Outer sheath | synthetic thermosetting compound, 5GM5 quality acc. to DIN VDE 0207/21 |

R-(N)TSCGEWÖU Cable Application

R-(N)TSCGEWÖU Cable is a flexible coiled cable specifically designed to withstand extremely high mechanical stress.

- Operable in both wet and dry environments, it is applicable for industrial facilities, underground and open-pit mining operations, as well as areas with explosion hazards.

- Connecting large mobile equipment such as excavators, loaders, and spreaders in open-pit mines.

- Powering equipment that continuously moves while performing winding/unwinding operations.

- Suitable for applications involving high mechanical loads, high-speed winding, and torsional stresses.

R-(N)TSCGEWÖU Cable Technical Data

| Rated Voltage U0/U | 3.6/6 kV | 6/10 kV | 8.7/15 kV | 12/20 kV |

| Max. operating voltage Um | 7.2 kV | 12 kV | 18 kV | 24 kV |

| AC test voltage | 11 kV | 17 kV | 24 kV | 29 kV |

| Partial discharge | 1.25U0/max 20 pC | |||

| Current carrying capacity | DIN VDE 0298-4 | |||

| Max. conductor operating temperature | +90°C | |||

| Max. conductor temperature during short circuit | +250°C | |||

| Minimum ambient temperature for fixed installation | -40°C | |||

| Minimum ambient temperature for mobile installation | -25°C |

R-(N)TSCGEWÖU Cable Standard

- DIN VDE 0250-813

R-(N)TSCGEWÖU Cable Feature

- Flexible Medium-Voltage Reeling Cable: Specifically engineered to withstand high mechanical stresses common in single-helix and cylindrical reels.

- Integrated Fiber Optics: Simultaneously fulfills communication and monitoring requirements during power transmission.

- Wide Temperature Mechanical Properties: Operates within extreme temperature ranges while resisting torsional stress and mechanical loads.

- High-Speed Operation: Suitable for rapid reel-to-reel rewinding without compromising cable integrity.

- Comprehensive Environmental Resistance: Features flame retardancy, oil resistance, ozone resistance, UV resistance, and seawater corrosion resistance to ensure extended service life in mining environments.

R-(N)TSCGEWÖU Cable Specification

| Number of cores x cross-section | Conductor diameter | Overall diameter | Approx. weight | Max. tensile load |

|---|---|---|---|---|

| mm2 | mm | mm | kg/km | N |

| 3.6/6 kV | ||||

| 3x25+3x25/3 | 6.6 | 39.9 | 2438 | 1500 |

| 3x35+3x25/3 | 7.8 | 42.5 | 2881 | 2100 |

| 3x50+3x25/3 | 9.4 | 46 | 3527 | 3000 |

| 3x70+3x35/3 | 11.2 | 51.7 | 4726 | 4200 |

| 3x95+3x50/3 | 12.9 | 55.4 | 5704 | 5700 |

| 3x120+3x70/3 | 14.7 | 59.3 | 6917 | 7200 |

| 3x150+3x70/3 | 16.4 | 64.7 | 8286 | 9000 |

| 3x185+3x95/3 | 18 | 68.2 | 9662 | 11100 |

| 6/10 kV | ||||

| 3x25+3x25/3 | 6.6 | 41.6 | 2589 | 1500 |

| 3x35+3x25/3 | 7.8 | 44.2 | 3041 | 2100 |

| 3x50+3x25/3 | 9.4 | 47.7 | 3703 | 3000 |

| 3x70+3x35/3 | 11.2 | 53.4 | 4922 | 4200 |

| 3x95+3x50/3 | 12.9 | 57.1 | 5911 | 5700 |

| 3x120+3x70/3 | 14.7 | 61 | 7138 | 7200 |

| 3x150+3x70/3 | 16.4 | 66.4 | 8528 | 9000 |

| 3x185+3x95/3 | 18 | 69.9 | 9916 | 11100 |

| 8.7/15 kV | ||||

| 3x25+3x25/3 | 6.6 | 45.1 | 2912 | 1500 |

| 3x35+3x25/3 | 7.8 | 47.7 | 3378 | 2100 |

| 3x50+3x25/3 | 9.4 | 52.9 | 4288 | 3000 |

| 3x70+3x35/3 | 11.2 | 56.9 | 5332 | 4200 |

| 3x95+3x50/3 | 12.9 | 60.6 | 6348 | 5700 |

| 3x120+3x70/3 | 14.7 | 66.2 | 7877 | 7200 |

| 3x150+3x70/3 | 16.4 | 69.9 | 9029 | 9000 |

| 3x185+3x95/3 | 18 | 75.1 | 10759 | 11100 |

| 12/20 kV | ||||

| 3x25+3x25/3 | 6.6 | 48.1 | 3209 | 1500 |

| 3x35+3x25/3 | 7.8 | 52.5 | 3912 | 2100 |

| 3x50+3x25/3 | 9.4 | 55.9 | 4636 | 3000 |

| 3x70+3x35/3 | 11.2 | 59.9 | 5646 | 4200 |

| 3x95+3x50/3 | 12.9 | 65.4 | 7020 | 5700 |

| 3x120+3x70/3 | 14.7 | 69.3 | 8316 | 7200 |

| 3x150+3x70/3 | 16.4 | 72.9 | 9486 | 9000 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

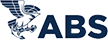

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees