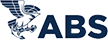

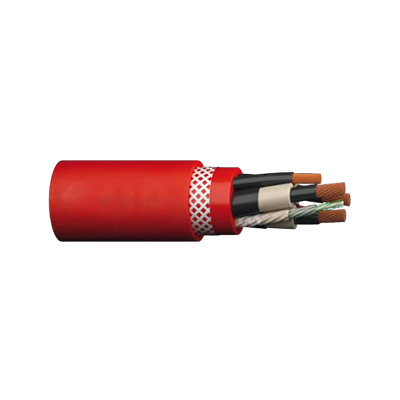

6.35/11 kV SANS Type 611 / 611-ECC Cable Construction

| Conductor | Class 5 flexible stranded tinned annealed Copper |

| Insulation | EPR (Ethylene Propylene Rubber) thermosetting compound and a strippable semi-conducting core screen (triple extruded) |

| Braid | Nylon /Tinned copper wires |

| Pilot Cores | Insulated with EPM (Ethylene Propylene Monomer) |

| Lay | Each power core individually screened with tinned copper/textile braid, laid up three insulated pilot cores |

| ECC Variant | One pilot core replaced with tinned conductor |

| Inner Sheath | CR (Polychloroprene Rubber) |

| Reinforcement braid | Open nylon braid - minimum 16 strings |

| Outer Sheath | CR (Polychloroprene Rubber) |

6.35/11 kV SANS Type 611 / 611-ECC Cable Application

- Main feeder circuits in 11kV distribution networks.

- Industrial power supply systems for factories and processing plants.

- Mining power distribution (surface and underground, subject to specific standards).

- Large commercial complexes and shopping centers.

- Collector circuits for renewable energy power plants (solar photovoltaic plants, wind farms).

- Water treatment and wastewater treatment plants.

6.35/11 kV SANS Type 611 / 611-ECC Cable Technical Data

- Voltage Rating Uo/U 6.35/11 kV

- Temperature Rating

- -25°C to +90°C

- Minimum Bending Radius

- 9 x Overall Diameter

6.35/11 kV SANS Type 611 / 611-ECC Cable Standard

- SANS 1520-2, SANS 1411-1, SANS 1411-3

6.35/11 kV SANS Type 611 / 611-ECC Cable Specification

| POWER CORES | PILOT CORES CORES | MAXIMUM TENSION | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CONDUCTOR SIZE | MAXIMUM WIRE DIAMETER | CONDUCTOR DIAMETER | MAXIMUM SCREEN WIRE DIAMETER | SCREEN CROSS- SECTION | CONDUCTOR SIZE | MAXIMUM WIRE DIAMETER | CONDUCTOR DIAMETER | |||

| mm2 | mm | mm | mm | mm2 | mm2 | mm | mm | kN | mm | kg/km |

| 25 | 0.41 | 6.8 | 0.31 | 29 | 10 | 0.41 | 4.2 | 1.1 | 50.7 | 410 |

| 35 | 0.41 | 8.5 | 0.31 | 31 | 10 | 0.41 | 4.2 | 1.6 | 52.2 | 450 |

| 50 | 0.41 | 10.3 | 0.31 | 34 | 10 | 0.41 | 4.2 | 2.3 | 59.4 | 530 |

| 70 | 0.51 | 11.9 | 0.31 | 37 | 16 | 0.41 | 5.3 | 3.2 | 60.4 | 650 |

| 95 | 0.51 | 13.5 | 0.31 | 41 | 16 | 0.41 | 5.3 | 4.3 | 65.2 | 800 |

| 120 | 0.51 | 15.5 | 0.31 | 43 | 16 | 0.41 | 5.3 | 5.4 | 71.3 | 980 |

| 150 | 0.51 | 17.3 | 0.31 | 46 | 25 | 0.41 | 6.8 | 6.8 | 75 | 1070 |

| 185 | 0.51 | 20.2 | 0.31 | 49 | 25 | 0.41 | 6.8 | 8.3 | 85.1 | 1340 |

| 240 | 0.51 | 22.9 | 0.31 | 52 | 25 | 0.41 | 6.8 | 10.8 | 85.6 | 1470 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees