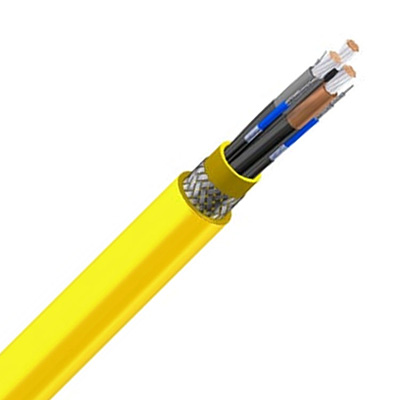

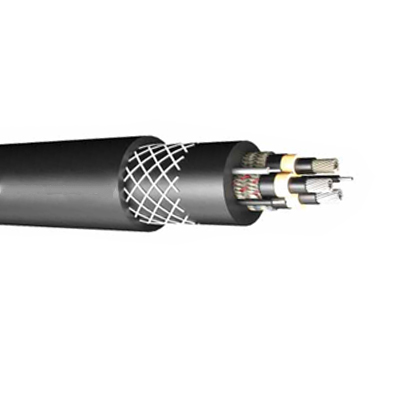

NSSHKCGEOEU Mining Cable Construction

| Conductor | Very finely stranded copper conductor, tinned (class FS) |

| PE-Conductor | Double-concentric control/PE wire spinning in the outer interstice |

| Insulation | PROTOLON, Basic material: EPR, Compound type: 3GI3 |

| Core identification | Main cores: Colored, Black, Grey, Brown; Control cores: Blue |

| Core arrangement | Three main conductors laid-up, with double-concentric control/PE conductor elements in the outer interstice |

| Inner sheath | Vulcanized rubber inner sheath, Basic material: EPR, Compound type: GM1B |

| Armouring | Braid of steel strands in a vulcanized bond between inner and outer sheath |

| Outer sheath | PROTOFIRM, Basis:synthetic elastomer compound e.g. CM, Compound type: 5GM5, Color: Yellow |

NSSHKCGEOEU Mining Cable Application

NSSHKCGEOEU cable is a heavy-duty, flexible rubber-sheathed power cable specifically designed for underground mining applications. Below are its specific application scenarios.

- Power supply for continuous mining machines

- Shuttle cars and haulage vehicles

- Mining machine drills and loaders

- Longwall mining machine power sources

- Other heavy mobile equipment suitable for underground coal mines or hard rock mines

NSSHKCGEOEU Mining Cable Standard

- DIN VDE 0250-812

NSSHKCGEOEU Mining Cable Technical Data

| Rated voltage | 0.6/1 kV (600/1000V) |

| Max. permissible operating voltage AC | 0.7/1.2 kV |

| Max. permissible operating voltage DC | 0.9/1.8 kV |

| AC test voltage | 3 kV |

| AC test voltage - control cores | 2 kV |

| Max. operating temperature of the conductor | 90 °C |

| Max. short circuit temperature of the conductor | 250 °C |

| Ambient temperature for fixed installation | min -40°C; max +80°C |

| Ambient temperature in fully flexible operation | min -20°C; max +60°C |

| Minimum Breaking load of steel braid | 45 kN |

| Max. tensile load on the conductor | 40 N/mm² |

| Torsional stress +/- | 10 °/m |

| Travel speed | 150 m/min |

NSSHKCGEOEU Mining Cable Feature

- Durability: Its robust construction makes it suitable for the most demanding and harsh environments in the mining industry.

- Safety: The built-in monitoring system provides early warnings for potential issues, preventing failures and ensuring a safer working environment.

- Performance: Maintains exceptional performance and reliability even under extreme conditions such as high-speed operation, oil contamination, humidity, and temperature fluctuations.

- Ultimate Flexibility: Specifically engineered for “drag-type” or “reel-type” cables, capable of repeated bending, coiling, and uncoiling as equipment moves.

- Superior Mechanical Protection: Heavy-duty rubber sheathing and robust construction effectively resist crushing, cutting, and severe abrasion caused by rough mine surfaces and sharp rocks.

NSSHKCGEOEU Mining Cable Specification

| Number of cores x cross section | Conductor diameter max. | Outer diameter min. | Outer diameter max. | Weight (approx.) | Permissible tensile force max. | Conductor resis- tance at 20°C max. | Nominal operating capacitance | Inductance nom. | Current carrying capacity (1) | Short Circuit Current (conduc- tor) |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | kg/km | N | Ω/km | µF/km | mH/ km | A | kA | |

| 3x25+3x(1,5STKON + 16/3KON) | 7.1 | 39.2 | 42.2 | 2700 | 3000 | 0.795 | 0.37 | 0.33 | 131 | 3.58 |

| 3x35+3x(1,5STKON + 16/3KON) | 8.4 | 40.8 | 43.8 | 3100 | 4200 | 0.565 | 0.42 | 0.3 | 162 | 5.01 |

| 3x50+3x(1,5STKON + 25/3KON) | 10.1 | 46.2 | 49.2 | 4000 | 6000 | 0.393 | 0.45 | 0.28 | 202 | 7.15 |

| 3x70+3x(1,5STKON + 35/3KON) | 11.9 | 49.6 | 53.6 | 5100 | 8400 | 0.277 | 0.52 | 0.27 | 250 | 10.01 |

| 3x95+3x(1,5STKON + 50/3KON) | 14 | 56.8 | 60.8 | 6700 | 11400 | 0.21 | 0.55 | 0.27 | 301 | 13.59 |

| 3x120+3x(1,5STKON + 70/3KON) | 15.5 | 60.6 | 64.6 | 8000 | 14400 | 0.164 | 0.59 | 0.26 | 352 | 17.16 |

| 3x150+3x(1,5STKON + 70/3KON) | 17.6 | 67 | 71 | 9620 | 18000 | 0.132 | 0.61 | 0.26 | 404 | 21.45 |

| 3x185+3x(1,5STKON + 95/3KON) | 19.1 | 72 | 76 | 11500 | 22200 | 0.108 | 0.63 | 0.26 | 461 | 26.46 |

| 3x240+3x(1,5STKON + 120/3KON) | 22 | 80.4 | 85.4 | 14600 | 28800 | 0.0817 | 0.67 | 0.25 | 540 | 34.32 |

| 3x300+3x(1,5STKON + 150/3KON) | 24.8 | 89.1 | 94.1 | 18700 | 36000 | 0.0654 | 0.7 | 0.25 | 620 | 42.9 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees