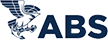

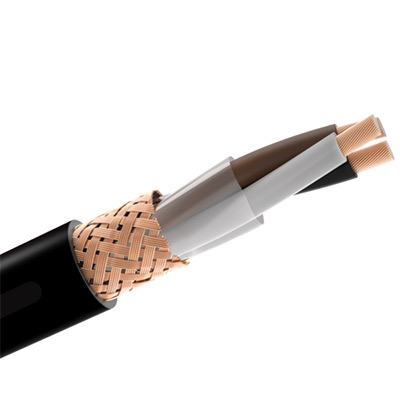

HF-EPR SW2/SW4 Cable Construction

| Conductor | Tinned copper wire stranded circular cl. 2 |

| Insulation | HF-EPR GP5 |

| Inner Sheath | Halogen free thermosetting compound SW4 or reduced halogen thermosetting compound SW2 |

| Armour | Galvanized steel wire braid or tinned bronze wire braid (single core). |

| Outer Sheath | Halogen free thermosetting compound SW4 or reduced halogen thermosetting compound SW2 |

HF-EPR SW2/SW4 Cable Application

- Ships and Offshore Platforms: Space-constrained environments requiring low-smoke, halogen-free materials.

- Oil and Gas Platforms and Refineries: Hazardous areas where fire safety is paramount.

- Power Plants and Substations: Ensuring critical auxiliary power and control systems remain operational.

- Mining Industry: Particularly in underground mines, mechanical protection and flame-retardant properties are essential.

- Railways and Tunnels: Traction power and signaling systems must prioritize public safety.

- Industrial complexes: Heavy industrial sites equipped with 3.3kV power distribution systems.

HF-EPR SW2/SW4 Cable Technical Data

| Minimum Internal Bending Radius | 6×OD |

| Temperature Range | -40℃ ~ +90℃ |

| Rated Voltage | 1.9/3.3kV 3.3/3.3kV |

HF-EPR SW2/SW4 Cable Standard

- BS 6883

- IEC 60332-3A Flame retardant

- IEC 60754-1; IEC 60754-2 Corrosivity

- IEC 61034-2 Smoke density

- Cold bend and impact (-40°C) (on request)

- CSA C22.2 No. 38-95 (on request)

HF-EPR SW2/SW4 Cable Feature

- Flame Retardant Properties: This cable meets stringent flame retardant standards, which are critical for marine environments.

- Halogen-Free Design: Utilizes halogen-free compounds to minimize the release of corrosive and toxic gases during fires, effectively safeguarding equipment and personnel.

- Heavy-Duty Armoring: Steel or copper braided layers provide robust mechanical protection against impacts and other damage.

- Wide Applicability: This cable series is suitable for various fixed wiring power and control systems on ships and mobile offshore platforms.

- 1.9/3.3kV HF-EPR SW2/SW4 Cable Specification

- 3.3/3.3kV HF-EPR SW2/SW4 Cable Specification

| Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Inner Sheath Thickness mm | Minimum Diameter Over Inner Sheath mm | Maximum Diameter Over Inner Sheath mm | Nominal Armour Wire Diameter mm | Nominal Outer Sheath Thickness mm | Minimum Overall Diameter mm | Maximum Overall Diameter mm | Approx. Weight kg/km |

|---|---|---|---|---|---|---|---|---|---|

| 1×10 | 2.2 | 1.1 | 10.2 | 11.9 | 0.3 | 1.3 | 14.2 | 16.2 | 398 |

| 1×16 | 2.2 | 1.2 | 11.4 | 13.1 | 0.3 | 1.3 | 15.4 | 17.6 | 499 |

| 1×25 | 2.2 | 1.2 | 13 | 14.8 | 0.3 | 1.4 | 17.1 | 19.5 | 675 |

| 1×35 | 2.2 | 1.3 | 14.1 | 15.9 | 0.3 | 1.4 | 18.2 | 20.6 | 793 |

| 1×50 | 2.2 | 1.3 | 15.3 | 17.2 | 0.3 | 1.5 | 19.6 | 22.4 | 970 |

| 1×70 | 2.2 | 1.4 | 17.2 | 19.2 | 0.3 | 1.6 | 21.7 | 24.6 | 1269 |

| 1×95 | 2.4 | 1.5 | 19.4 | 21.9 | 0.3 | 1.7 | 24.2 | 27.2 | 1623 |

| 1×120 | 2.4 | 1.6 | 21.3 | 23.8 | 0.3 | 1.7 | 26 | 29.1 | 1983 |

| 1×150 | 2.4 | 1.6 | 22.8 | 25.4 | 0.45 | 1.8 | 28.4 | 31.6 | 2423 |

| 1×185 | 2.4 | 1.7 | 24.8 | 27.4 | 0.45 | 1.9 | 30.6 | 34.3 | 2917 |

| 1×240 | 2.4 | 1.8 | 27.5 | 30.3 | 0.45 | 2 | 33.5 | 37.3 | 3654 |

| 1×300 | 2.4 | 1.9 | 30 | 33.2 | 0.45 | 2.1 | 36.2 | 40.1 | 4428 |

| 1×400 | 2.6 | 2 | 33.8 | 37.1 | 0.45 | 2.3 | 40.3 | 44.8 | 5416 |

| 1×500 | 2.8 | 2.2 | 37.6 | 41.1 | 0.45 | 2.5 | 44.5 | 49.2 | 6726 |

| 1×630 | 2.8 | 2.3 | 41.2 | 45.2 | 0.45 | 2.6 | 48.4 | 53.6 | 8562 |

| 3×10 | 2.2 | 1.5 | 20.4 | 22.9 | 0.3 | 1.7 | 25.1 | 28.2 | 1052 |

| 3×16 | 2.2 | 1.6 | 22.8 | 25.3 | 0.3 | 1.8 | 27.7 | 30.8 | 1357 |

| 3×25 | 2.2 | 1.8 | 26.6 | 29.3 | 0.45 | 2 | 32.6 | 36.3 | 2032 |

| 3×35 | 2.2 | 1.8 | 28.4 | 31.2 | 0.45 | 2.1 | 34.6 | 38.5 | 2382 |

| 3×50 | 2.2 | 1.9 | 31.2 | 34.4 | 0.45 | 2.2 | 37.6 | 41.6 | 2936 |

| 3×70 | 2.2 | 2.1 | 35.3 | 38.7 | 0.45 | 2.4 | 42.1 | 46.7 | 3877 |

| 3×95 | 2.4 | 2.3 | 40.2 | 44.1 | 0.45 | 2.6 | 47.4 | 52.1 | 4995 |

| 3×120 | 2.4 | 2.4 | 44 | 48.1 | 0.45 | 2.7 | 51.4 | 56.7 | 6118 |

| 3×150 | 2.4 | 2.6 | 47.6 | 51.8 | 0.45 | 2.9 | 55.3 | 60.8 | 7284 |

| 3×185 | 2.4 | 2.7 | 51.7 | 56.4 | 0.45 | 3 | 59.6 | 65.7 | 8750 |

| 3×240 | 2.4 | 3 | 57.7 | 62.9 | 0.45 | 3.3 | 66.2 | 72.6 | 11118 |

| 3×300 | 2.4 | 3.2 | 63.1 | 68.6 | 0.45 | 3.5 | 72 | 79 | 13531 |

| Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Inner Sheath Thickness mm | Minimum Diameter Over Inner Sheath mm | Maximum Diameter Over Inner Sheath mm | Nominal Armour Wire Diameter mm | Nominal Outer Sheath Thickness mm | Minimum Overall Diameter mm | Maximum Overall Diameter mm | Approx. Weight kg/km |

|---|---|---|---|---|---|---|---|---|---|

| 1×10 | 3 | 1.2 | 12 | 13.7 | 0.3 | 1.4 | 16.1 | 18.4 | 483 |

| 1×16 | 3 | 1.2 | 13 | 14.7 | 0.3 | 1.4 | 17.1 | 19.4 | 579 |

| 1×25 | 3 | 1.3 | 14.7 | 16.7 | 0.3 | 1.5 | 19.1 | 21.5 | 774 |

| 1×35 | 3 | 1.3 | 15.6 | 17.6 | 0.3 | 1.5 | 19.9 | 22.8 | 885 |

| 1×50 | 3 | 1.4 | 17 | 19 | 0.3 | 1.6 | 21.5 | 24.4 | 1082 |

| 1×70 | 3 | 1.5 | 18.9 | 21 | 0.3 | 1.6 | 23.4 | 26.4 | 1377 |

| 1×95 | 3 | 1.5 | 20.6 | 23.1 | 0.3 | 1.7 | 25.3 | 28.4 | 1699 |

| 1×120 | 3 | 1.6 | 22.5 | 25 | 0.3 | 1.8 | 27.4 | 30.5 | 2081 |

| 1×150 | 3 | 1.7 | 24.1 | 26.8 | 0.45 | 1.9 | 30 | 33.6 | 2550 |

| 1×185 | 3 | 1.7 | 26 | 28.6 | 0.45 | 2 | 32 | 35.7 | 3032 |

| 1×240 | 3 | 1.8 | 28.7 | 31.8 | 0.45 | 2.1 | 34.8 | 38.7 | 3780 |

| 1×300 | 3 | 1.9 | 31.2 | 34.4 | 0.45 | 2.2 | 37.6 | 41.5 | 4563 |

| 1×400 | 3 | 2.1 | 34.7 | 38.1 | 0.45 | 2.3 | 41.3 | 45.8 | 5514 |

| 1×500 | 3.2 | 2.2 | 38.4 | 41.9 | 0.45 | 2.5 | 45.3 | 50 | 6807 |

| 1×630 | 3.2 | 2.4 | 42.2 | 46.2 | 0.45 | 2.6 | 49.4 | 54.6 | 8691 |

| 3×10 | 3 | 1.7 | 24.1 | 26.7 | 0.45 | 1.9 | 29.9 | 33.6 | 1404 |

| 3×16 | 3 | 1.8 | 26.5 | 29.2 | 0.45 | 2 | 32.5 | 36.2 | 1738 |

| 3×25 | 3 | 1.9 | 30.1 | 33.2 | 0.45 | 2.1 | 36.3 | 40.2 | 2314 |

| 3×35 | 3 | 2 | 32.1 | 35.4 | 0.45 | 2.2 | 38.5 | 42.9 | 2701 |

| 3×50 | 3 | 2.1 | 34.9 | 38.3 | 0.45 | 2.3 | 41.5 | 46 | 3278 |

| 3×70 | 3 | 2.2 | 38.9 | 42.7 | 0.45 | 2.5 | 45.8 | 50.5 | 4226 |

| 3×95 | 3 | 2.4 | 42.9 | 46.9 | 0.45 | 2.7 | 50.2 | 55.5 | 5297 |

| 3×120 | 3 | 2.5 | 46.7 | 50.9 | 0.45 | 2.8 | 54.2 | 59.7 | 6442 |

| 3×150 | 3 | 2.7 | 50.3 | 54.9 | 0.45 | 3 | 58.2 | 64.2 | 7631 |

| 3×185 | 3 | 2.8 | 54.4 | 59.2 | 0.45 | 3.2 | 62.7 | 68.9 | 9158 |

| 3×240 | 3 | 3.1 | 60.4 | 65.7 | 0.45 | 3.4 | 69.1 | 76 | 11526 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees