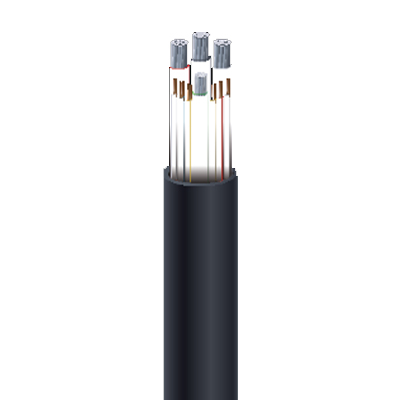

600V Copper Generator Cable Construction

| Conductor | Element 1: Annealed bare copper Class C |

| Element 2: Annealed bare copper Class K | |

| Element 3: Annealed bare copper Class C | |

| Insulation | Element 1, 2 & 3: Polyvinylchloride (PVC) & Nylon |

| Assembly | All 3 Elements or Conductors are cabled together with Non Hygroscopic Polypropylene fillers as required for a circular cross-section with a clear mylar binder tape and jacketed |

| Jacket | Black sunlight & flame resistant and direct burial approved PVC with ripcord rated 75/90℃ wet or dry per UL 1277 |

600V Copper Generator Cable Application

- Generator Wiring: Primary Use—Connecting portable or standby generators to manual transfer switches.

- Power Entry Box: Introducing generator power into a building’s electrical system.

- Industrial Machinery: Powering heavy-duty tools, welders, and construction equipment.

- Marine and RV: Shore power connection applications.

- Mining and Temporary Power: Suitable for any scenario requiring durable, flexible, and oil-resistant power cables.

600V Copper Generator Cable Standard

- UL Listed as TC-ER-JP per UL Standard 1277

- Rated 75°C wet or dry to meet UL 83 for THHN/THWN

- Meets cold bend test at -40°C

- ICEA S-73-532

- Meets UL 1581 & 1202 (FT-4) 70,000 BTU/HR & ICEA T-29-520 210,000 BTU/HR requirements

- REACH compliant per Regulation (EC) No 1907/2006 (197) Updated January 15, 2019

- Cable is suitable for use in Class I Division 2 hazardous locations

- Element 1 & 2 conductors pass UL VW-1 flame test, rated THWN/VW-1

- ASTM B3, B174, B801

600V Copper Generator Cable Feature

- Exceptional Durability: The nylon-coated PVC construction significantly enhances resistance to physical damage, chemical corrosion, and abrasion compared to standard PVC cables.

- Superior Flexibility: The stranded copper core combined with a flexible insulation/sheath design greatly simplifies installation.

- Ideal for Harsh Environments: Suitable for generator perimeters, industrial plants, machine shops, and outdoor settings, it withstands demanding conditions including oil contamination, chemical exposure, and physical abrasion.

- Safe and Reliable: With a 600V rated voltage and robust construction, it delivers high safety margins for critical power applications.

600V Copper Generator Cable Specification

| Section | Conductor Size | No. of Conductors | No. of Strands | Insulation Thickness | Nylon Thickness | Jacket Thickness | Overall Diameter | Net Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AWG | Inches | mm | Inches | mm | Inches | mm | Inches | lbs/kft | ||||

| 6 Core | Element 1 | 8 | 3 | 19 | 0.03 | 0.76 | 0.006 | 0.15 | ||||

| Element 2 | 18 | 6 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | |||||

| Element 3 | 10 | 1 | 19 | 0.048 | 1.22 | 0.004 | 0.1 | |||||

| Overall | 0.06 | 1.52 | 0.648 | 363 | ||||||||

| Element 1 | 4 | 3 | 19 | 0.04 | 1.02 | 0.007 | 0.18 | |||||

| Element 2 | 18 | 6 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | |||||

| Element 3 | 8 | 1 | 19 | 0.03 | 0.76 | 0.005 | 0.13 | |||||

| Overall | 0.08 | 2.03 | 0.892 | 750 | ||||||||

| Element 1 | 3 | 3 | 19 | 0.04 | 1.02 | 0.007 | 0.18 | |||||

| Element 2 | 18 | 6 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | |||||

| Element 3 | 8 | 1 | 19 | 0.03 | 0.76 | 0.005 | 0.13 | |||||

| Overall | 0.08 | 2.03 | 0.951 | 865 | ||||||||

| 8 Core | Element 1 | 3 | 3 | 19 | 0.04 | 1.02 | 0.007 | 0.18 | - | - | - | - |

| Element 2 | 18 | 8 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | - | - | - | - | |

| Element 3 | 8 | 1 | 19 | 0.03 | 0.76 | 0.005 | 0.13 | - | - | - | - | |

| Overall | - | - | - | - | - | - | - | 0.08 | 2.03 | 0.951 | 885 | |

| 9 Core | Element 1 | 2 | 3 | 19 | 0.04 | 1.02 | 0.007 | 0.18 | BK, RD, WT | |||

| Element 2 | 18 | 9 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | BK, RD, YL, YL/BK, BL, WT, WT/BL, PU, PU/BK | ||||

| Element 3 | 6 | 1 | 19 | 0.03 | 0.76 | 0.005 | 0.13 | Green Ground | ||||

| Overall | 0.08 | 2.03 | 1.013 | 1070 | ||||||||

| Element 1 | 3 | 3 | 19 | 0.04 | 1.02 | 0.007 | 0.18 | BK, RD, WT | ||||

| Element 2 | 18 | 9 | 16 | 0.015 | 0.38 | 0.005 | 0.13 | BK, RD, YL, YL/BK, BL, WT, WT/BL, PU, PU/BK | ||||

| Element 3 | 8 | 1 | 19 | 0.03 | 0.76 | 0.005 | 0.13 | Green Ground | ||||

| Overall | 0.08 | 2.03 | 0.983 | 903 | ||||||||

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees